We read a lot of articles on the brewing process, and lately we came across two that addressed the issue of the dreaded stuck sparge. The sparge is post mash washing of the sugars from the grains and is accomplished by methodically adding just enough water to the mash tun to "float" the top portion of the grain bed. To allow outflow some sort of manifold with approximately 1/16" holes is inserted in the bottom of the tun. This lets gravity and pressure work together to provide an outlet for the heavier sugar laden wort. The manifold is connected to a valve that the brewer controls because if the wort is released too fast or water added too slow the result is a slow or stuck sparge. There are other circumstances that contribute to the stuck sparge but we think you get what we’re talking about.

Some brewers deviate from traditional fly or sprinkle sparging by filling the mash tun with water and when the mash is complete, slowly releasing all of it into the boil kettle and then doing that again. That’s called batch sparging but we don’t know why as all methods sparge all of the batch. That technique is so close to full volume mashing that we can’t figure out why the brewer just doesn’t go on and do it. Anyway, we did a bit more searching and reading and discovered that you’ll find the same list of “don'ts” from every author on this subject.

We find this interesting because in spite of chapters on how to maximize efficiency using various methods of sparging, the one thing that has been proven to increase efficiency and aid in a faster more thorough conversion is never suggested; and that one thing is a finer crushing of the grain - and we mean as low as the mill will allow, like to .020. Not doing this is counter to maximizing conversion as it’s related to kettle efficiency and we think the lack of this obvious suggestion can only be explained by the stuck sparge fear factor. And it seems that sparging one way or another with a “safe” mill setting determines the average acceptable ceiling regarding efficiency, and well, the common knowledge passed on, or frankly not known, is that you have to sacrifice efficiency to avoid a stuck runoff.

Another proven advantage that’s never mentioned regarding efficiency is to simply increase the water volume while mashing. Troester confirmed this and brewers have proven his findings, but no one besides us that we know of advises this option. Even if a safe mill setting was combined with a higher mash water volume the numbers go up. So, what if you did both with no concern of stuck runoff? We can tell you that fabric filter brewer’s combine a higher water to grain ratio with a finer crush with very positive results which include 78.5% average kettle efficiency.

As a hint at substantiation across a broad base of brewing recipes, flip through the pages of any brewing magazine and you’ll consistently find assumed efficiency listed at 72% or 73%, maybe 74% but you’ll never find assumed efficiency of 78.5% listed in the profile notes - which is the average of brew in bag brewers. So everyone assumes that 73% is the baseline for most sparge low-water-volume-mash recipes and that low average is conclusively linked to the coarse mill setting which aids in avoiding a stuck sparge - and that sparge set ups toss sugar laden wort left in the mash tun. We know that some brewer's achieve higher efficiencies, but not all brewers, and why not?

We’ll also mention here that higher average efficiencies could be obtained if these sparge brewers could get at the trapped sugar that is left behind in the mash tun sparge water and grain. Common sparging knowledge says to stop sparging when the gravity hits 1.008 which means (sugar x volume = Y - left behind in the mash wort) - not including what's been absorbed by the grain. To get at part of that sugar you'd have to break another rule that's called "over-sparging". Over sparging is said to release tannins and add astringency to the beer. So to avoid that bitter conundrum the only option for sparge brewers is to reduce maximum efficiency by leaving sugary wort in the tun and in the grain - and throwing it out.

When performing a full volume mash along with squeezing the grain bag ALL of this sugar / wort is transferred to the boil kettle. And we'll say it again - there is no sugar laden wort left behind. So instead of limiting the kettle efficiency potential of the grain by milling at a safe-no-stuck-runoff setting, we think brewers would benefit from understanding how to optimize and capture the extraction potential of the grain bill by starting the brew day with disregard of a stuck runoff. Literally brewing from the grain forward instead of from the equipment "common use and knowledge" limitations backward.

The use of a true filter - not the persnickety volatile grain bed which changes every brew - alters the dynamics of the brewing process and allows maximum conversion and extraction with a fixed pH and total capture of available wort.

Here’s the commonly accepted list of “don'ts” that if ignored will surely set up the potential for a stuck runoff. We’ve added “do’s” to offer a perspective that not only turns a don’t into a do, but also justifies an action toward a shorter more efficient brew session. You too can average 78.5% efficiency in 3.5 hours or less. In no particular order they follow.

Don’t over crush the grain. The degree to which the grain is crushed impacts conversion, kettle efficiency, and time to convert. These are three key points in homebrewing, so sacrificing the potential of any one of them let alone all three to avoid a stuck runoff, is counter to home brewing goals.

Rather than grinding the grain at .015 or .020 to expose the highest degree of endosperm surface area to water, most sparge brewers and home brew stores alike set their mills between .035 and .049. The logic in the wider mill gap is that the grain needs to be crushed well but the husks left mostly intact as they separate from the grain. The combination of mostly intact grain husks and grain bits creates a permeable sediment bed that filters the sparge water/wort into the boil kettle.

You’re told to avoid mills that slice or shear the grain and husk (Corona) or the husks will be too small and be of no value in fluffing the grain bed. Without the fluffy grain husks the grain bed becomes gummy or sticky and decreases the effectiveness of sparging due to channeling, no flow at all through the bed, or equally as bad, a gummed pick up. Channeling occurs when the sparge water runs through crevices in the grain bed rather than the grain bed being “lifted” as a whole by the sparge water. This means the majority of the grain is not washed of the sugars and kettle efficiency suffers.

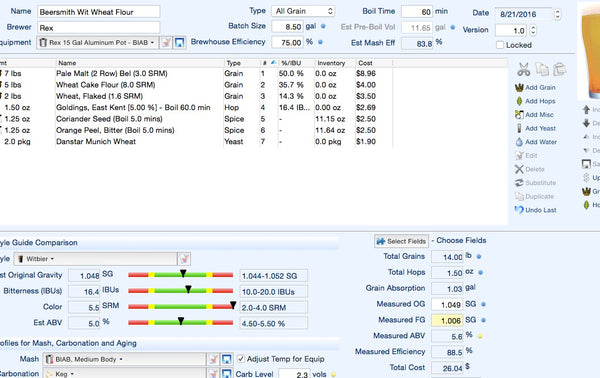

Do use a fabric filter and crush the grain as fine as your mill will allow. This sets the potential extraction, conversion, and time spent to their maximum values. As proven by Troester, a water-to-grain-ratio of 2.6 or greater positively influences kettle efficiency and time to convert, so even if your mash tun will not allow the 2.6 ratio, boost the mash water volume as high as you can and sparge with less volume and you’ll see your kettle efficiency rise. Bear in mind that when using a fabric filter there is no dead space calculation and no lost wort - none - and you should squeeze the most wort out of the grain as possible. To provide substantiation we have included a screenshot of a recipe that includes five pounds of wheat flour purchased from a local grocery store. Because the grain bill was average for an 8.5 gallon batch, but because we had no idea what the effect of wheat flour would be, we set the brewhouse efficiency a bit low at 75%. You can see the actual efficiency was 88.5% and the beer turned out as good as anticipated.

On lifting the bag it drained as usual, but as it drained the grain settled and with approximately four gallons left in the bag the draining slowed. Assuming the wheat flour was clogging the holes in the fabric, we jostled the bag and it began to drain well again. The point is we used seven pounds of barley, two pounds of flaked oats, and five pounds of wheat flour - with no stuck runoff, 88.5% efficiency, and no rice hulls!

- Speaking of Rice Hulls

Don’t forget the rice hulls. To be sure there will be no stuck runoff add a few cups of rice hulls to every batch. Rice hulls act to separate the grain bed and allow the sparge water to float the grains and thoroughly rinse the sugars into the boil kettle. Because unmalted wheat, rye, and oats create difficult lautering due to the production of “gel”, rice hulls are considered a must-have item on the grain bill.

Do cross rice hulls off the grain bill. Fabric filters are true filters which allow the separation of liquids from certain sized solids. Additional filtering medium is not required for consistent outflow of wort into the boil kettle. Most kettles or mash tuns using a fabric filter take advantage of 1,200 square inches or more of filtering surface area. Most mash tun bottom pickups rely on 24” or less of duct flow surface area and are negatively influenced by the instability of the ever-changing grain bed filter above them.

- Mash out or keep the temp warm.

Don’t let the temperature of the mash drop below 145ºF or the mash will start to gelatinize. “Gel” is a result of starchy grain like wheat, rye, or oats and will prevent the sparge water from moving through the grain bed. If it makes it to the holes in the bottom pick up it will surely clog. To prevent this, use water heated to 168º F to sparge. This is called the “mash out,” which simply means to stop the mash process. We don’t mean to be coy here, but you’ve just spent the better part of two hours doing everything you know to create a mash environment that promotes the conversion of starch to sugar - why would you want to stop that process? Most often the answer is “to set the sugar profile” which ensures a consistent end product. Another explanation is to make the grain bed/wort less viscous so the wort moves into the boil kettle more readily.

Do use a fabric filter and simply lift the bag when done mashing. The simplest explanation for the single step of lifting the grain out of the wort is to state that when the bag is lifted the sugary wort transfers to the boil kettle in less than 10 minutes using gravity and a few squeezes of the bag. There is no opportunity for the wort to gelatinize or clog the fabric filter. The wort is then immediately fired up to boil, which denatures the enzymes thereby locking the sugar profile. When employing full-volume mashing, viscosity of the wort is not a factor. In addition, since there is no dilution caused by sparging, the pH of the wort is stable and every drop of wort that can be delivered to the boil kettle is done so in a few minutes with only seven ounces or so trapped in the grain. That is far less than when sparging where kettle capacity or pH determine the boil volume and ultimately how many beers make it into your glass.

- Create a vacuum vent.

We have no idea what this is and we don’t care to know. Using a fabric filter eliminates any consideration of whatever this is.

- Make sure your mash tun is of stable design.

Don’t use a poorly designed mash tun. Build a mash tun that not only allows an even sparge across the broadest surface area relative to the depth, but also construct or purchase a bottom pick up, or false bottom, that spans the length and width of the tun and also considers the depth of the grain bed, or just go to the hardware store and buy a toilet hose water fitting and strip the tube out of the inside and clamp the hose to your tun outlet. Prepare to sparge for at least thirty minutes and as long as two hours. Did you get all that? First let us say - this method of moving the wort from the tun to the boil kettle works and many brewers wouldn’t do it any other way. But until you understand the flows, levels, and grain mixture variances, you will likely experience a stuck runoff, poor kettle efficiency, or low volume due to over or under sparging.

Do use a fabric filter and eliminate buying or building anything else. You will still have a learning curve, but the bag compensates for variables in grain mix including gelatinous grain bills and reduces your brew session to about three hours. And you can use a fabric filter to brew any size batch up to 30 gallons in the same amount of time as brewing 5 gallons. When using a fabric filter you only need one kettle and a heat source and some sort of insulation. You’ll need a kettle or tun approximately 1.5x the size of your fermenter volume, so a five-gallon batch requires at least an 8-gallon kettle etc. If you go over 5 gallon batches it is best to consider using a pulley to lift and suspend the bag. Bear in mind that one pound of grain absorbs sixteen ounces of water, so a 15-pound grain bill will weigh 30 pounds not including the initial water retained in the bag, so about 45 pounds initial lift. No matter your stature, lifting a bag can be precarious and should not be considered unless safety is first.