As a viable small business, we're about 11 months in and happy to report that The Brew Bag is growing nicely. When the reality that the market was underserved with a strong reliable brew bag way back in January of 2013, I thought I would be supplying home brewers with bags, and that's about it. What has happened however, is more than that.

Home brewer's are an independent lot. I know this because I'm one of them, and I talk to a lot of them on social media, the phone, and via this site. An important aspect of home brewing is that the individual gets to brew beer - their way. And it's rare that two guys do the same thing every time. To that end there is a lot of "misinformation" that gets spread around and quite a few urban legends take root because, well, otherwise they wouldn't be legendary. On FB someone consistently drops a legend bomb and all hell breaks loose. Some guys "confirm" the legends by stating that since they adapted the legendary technique, either their beer got better, or worse, or they had better dreams, or whatever. Then the snopes brewing czars commence to pounding the legend to death and generally the result is the same. Home brewer's go back to brewing the same way they always have, because the beer is worth drinking.

Brew In A Bag is an urban truth, but is still viewed as a legend by many. There are however legends inside of legends. Here's one - "I get better efficiency when I sparge my bag". No, you don't, and frankly, I'm the czar of that reality and I can prove it so assuredly that you'll either thank me for saving you the time or be left flabbergasted. Inevitably, you measured the increase in efficiency post-boil - not pre-boil, or your grain bill was heavy, or you missed your water mark by two quarts. If I write this 100 times on the blackboard, Johnny is going to tell his buddy it's true. The reason brew in a bag can be a no sparge process is because of the filter the process employs. That's the whole enchilada in one sentence. It's ALL about the filter.

In three vessel brewing everything leading up to the boil is about protecting the grain bed so the lautering steps do not end with a restricted or no-flow of wort. Rice hulls are added to the tun, braided hoses are inserted, manifolds are cut with precision, and sparge water is heated to the correct temp. The grind is criticized as too fine or too coarse and efficiency is blamed on the LHBS's poor milling. S-L-O-W-L-Y add the water so the sugar washes through the bed without channeling - don't stir, OMG! don't upset that grain bed!

The brew in a bag process frees the brewer from the concern of the grain bed's condition. He rules over it, not it over him. The reason is the filter.

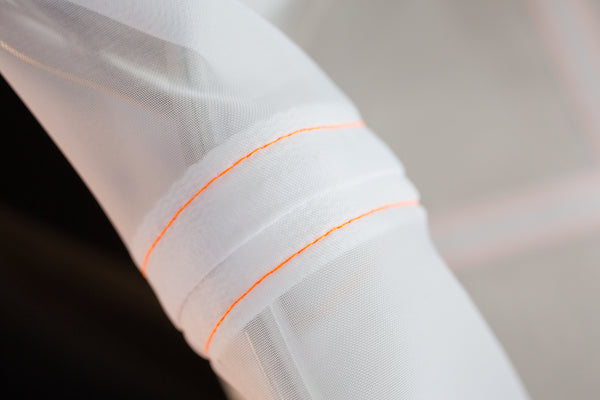

The Brew Bag is a filter 50X larger than the filter found in traditional 3V home brewer lauter tuns. Most braided hoses are 20 to 24 square inches, most manifolds have 50 to 75 holes - The Brew Bag is over 1,000 square inches of incredibly strong fabric that filters wort as fast as it can be lifted out of the kettle. And there is NO dead space - no loss of wort.

Brew In a Bag and 3V brewer's are after the same thing - sweet wort ready to boil. The first gets you there in 60 - 75 minutes - the second in 120 or so. The reason is the filter.

Brew In a Bag = NO sparge, NO rice hulls, NO second kettle, NO second burner, NO three tier stand, NO stuck sparge, NO dead space, NO clogged plate chiller, NO unhappy wife (because you spent all day brewing). The reason is the filter.

So maybe you're like me and need glasses to see the difference in these two filters...or, maybe not.

I’m a believer …and when you add no-chill, you really free-up time …and that time can be used for creativity.

I want clarity so will try brewbags next few batches.

Amen Brother! Glad you caught the wave of BIAB bags. I had the idea and had a few prototypes made by a local seamstress last year, but never was able to nail it. Congrats!